Establishing Robust Procurement Processes for Inventory Optimization

Home / Business Cases

Presentation

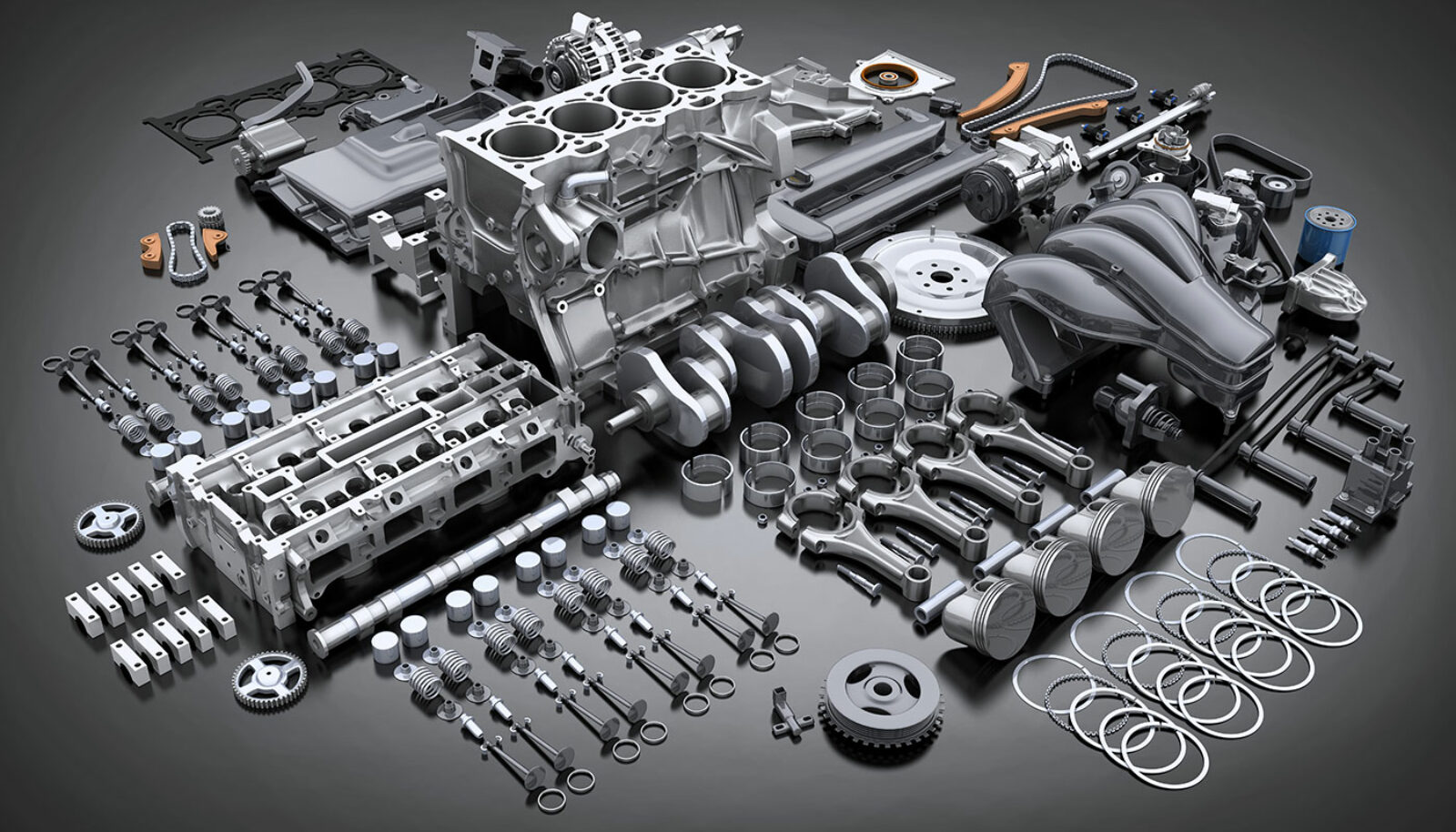

Our client, an automotive manufacturer, wants to set up robust procurement processes to optimize its inventory. KEPLER offers to conduct a revision of the stock management rules and animation rituals to optimize inventory performance and strengthen responsiveness to the risk of stock shortages.

Context

- Two factories in France for unlicensed and utility vehicles

- Over 1250 components common to the two sites, with local supplies, generating high stock coverage

- Inventory levels amplified by the Covid context

- Several Asian suppliers with long delivery times and imposing minimum orders

- Saturated teams managing supplies in «firefighter mode»

Objective(s)

Category: Improving Responsiveness and Securing Availability

-

Updating supply parameter settings

-

Challenging replenishment thresholds

-

Setting up robust coordination supported by visual management (boards) allowing group synergies

Beyond the analysis carried out on inventory management rules and the coaching of supply teams, visual management allows to decompartmentalize local procurement initiatives and share good practices, generating group synergies.Lysianne Bessonnet, Director - Supply Chain Practice Leader

Complete Version