Supply Chain Planning or S&OP in the New Normal

The global pandemic has highlighted the need to guard against new Supply Chain hazards in the future. In several surveys carried out between 2020 and 2021* and relating to the levers to make Supply Chain more robust and agile, most respondents stated a more frequent S&OP among the solutions to be considered a priority.Nirmal Govinda, Manager

S&OP or Sales & Operations Planning: what are we talking about?

S&OP is a process that aims to develop tactical plans to enable management to steer its business strategically. Over time, a proper S&OP should provide organizations with a competitive advantage to manage their supply chain that fully integrates customer-focused marketing plans for existing and future product lines.

The S&OP process aims to integrate all of the company’s functions into a single plan: from procurement to sales, including marketing, product development, manufacturing, purchasing, and finance.

Periodically reviewed by management (and piloted by the Supply Chain), this process, which tends to reconcile supply and demand, is most often carried out on a monthly scale and at the product family level. The S&OP process, a tactical version of the strategic plan, is directly linked to the Business Plan.

The main benefits expected from an S&OP process

- Improved customer service rate

- Better inventory management

- Alignment between stakeholders in the company

- Better visibility given to critical suppliers (especially for supplies subject to long lead-times)

- Better anticipation of CAPEX / OPEX

In what context do we deal with S&OP?

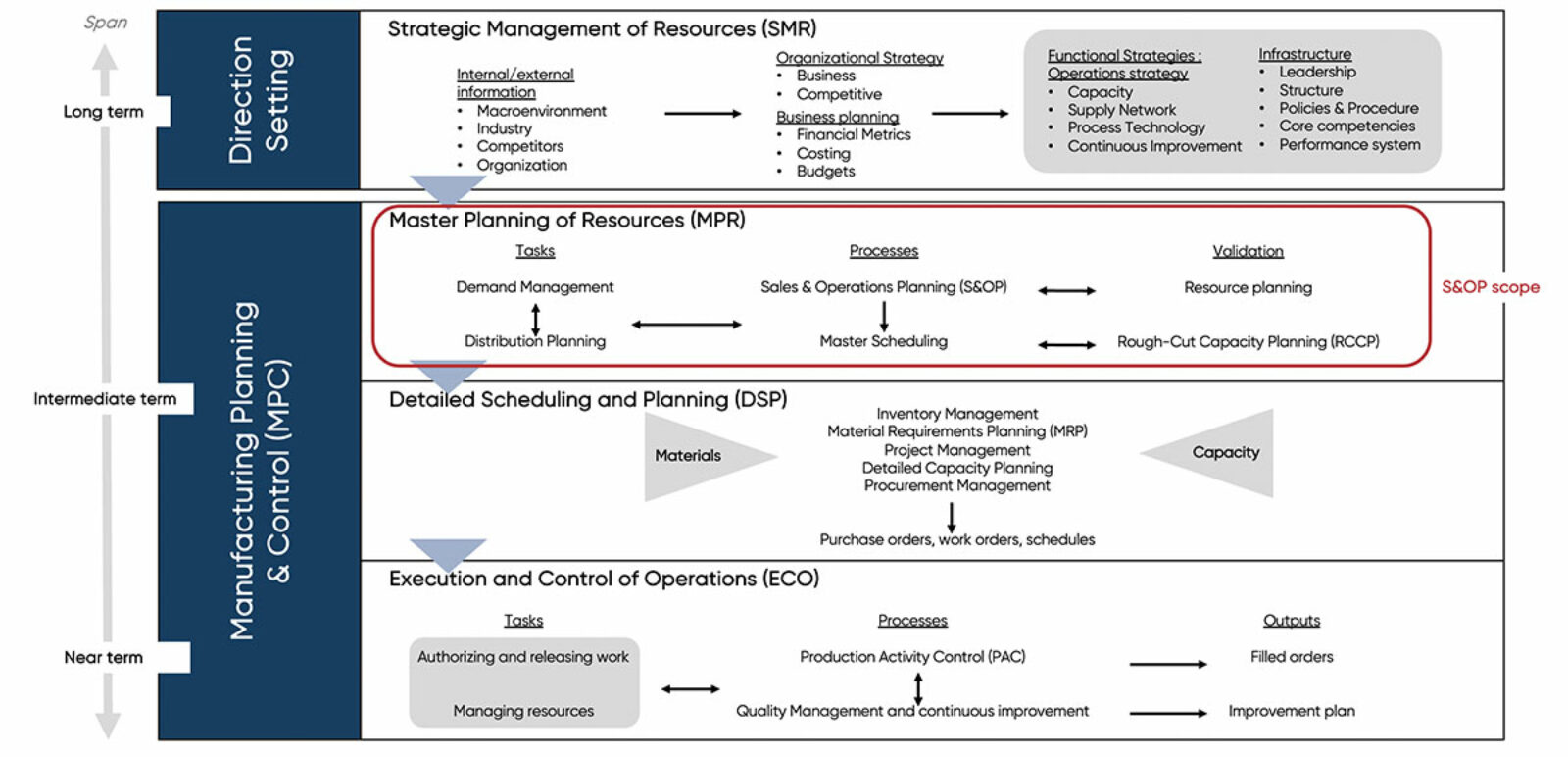

As an extension of strategic and long-term resource planning (also called SMR or Business Plan), the tactical and operational management of these same resources is broken down into three components:

- Master Resources Schedule

- Detailed Scheduling and Planning

- Execution and Control of Operations

S&OP Scope

Focus on the Master Planning of Resources (MPR)

The Master Resources Plan (MPR) is the medium-term operationalization (on a scale generally ranging from 18 to 24 months) of the Business Plan.

It is intended to answer, on a finer scale than the Business Plan, namely the family of products, to questions of production (what we are going to produce and how), sourcing (where and when we are going to make), and delivery (where and how the product will be delivered to customers). In the context of this MPR, the S&OP process takes place. Modeling work is necessary for its implementation.

In general, the Business Plans are not sufficiently connected to the S&OP. There are links made with the budget, but their time horizon is often too short. The challenge of knowing how to translate euros into operating expense drivers is evident to us.Edouard Alquie, Directeur, leader de la practice Opérations

Conducting an S&OP process from an operational point of view

The 5 steps of Sales & Operations Planning (or S&OP)

A process usually repeated on a monthly basis

Product Review

Conducted punctually

- Objective: Validate the product portfolio

- Attendees: R&D, Marketing, Sales, Supply Chain

Demand Review

Week 1

- Objective: Validation of the Demand plan

- Attendeed: Supply Chain via Demand Planning, Sales, Marketing

Supply Review

Week 2

- Objective: Validation of the Supply plan

- Attendees: Supply Chain via supply planning, production/factory manager, industrial management, subcontractors

Reconciliation or Pre-S&OP

Week 3

- Objective: Refine scenarios

- Attendees: Finance, Sales, Supply Chain, Marketing, Procurement

Executive S&OP

Week 4

- Objective: Arbitration and final validation

- Attendees: Excom, General Management

At the end of this monthly process, the final stage of Executive S&OP acknowledges the successful implementation of the long-term plan set by management.

A successful Sales & Operations Planning?

In an ideal world, everything goes as planned, and Executive S&OP comes down to reporting in line with the expected. But that never happens! Most often, and depending on the level of complexity of the organization, the Executive S&OP imposes the holding of arbitrations related to issues that impact the Supply Chain and, more generally, the tactics of the company. An S&OP is perfectly successful when different scenarios/alternatives are analyzed, and the process leads to a decision.

Note: it is crucial to ensure that the questions dealt with in Executive S&OP cannot be dealt with at a lower level and that they relate to a time horizon equivalent to the projected objective: is it justified to deal with this point during this meeting, are we in the presence of a question relating to the medium/long term?

Some examples of arbitrations legitimately handled during the Executive S&OP

- Is launching a new range of products for this market relevant to our ability to deliver? Should we shift it?

- Should we review our industrial organizations in the long term (2×8, 3×8, weekend openings)?

- We cannot deliver to all of our customers because the volumes of country Z have increased by 30% vs. the budget; what should we do? Increase product allocation by opening a more extensive product range or subcontracting? Reduce the overall stock level and take the risk of degrading its service level? Concentrate the drop in volume on countries deemed less of a priority?

A classic flaw observed in less mature organizations is letting too many operational questions take precedence (e.g. “Where are the five packages from customer X that we cannot currently locate…?”).

Bodies must exist parallel to resolve these operational issues and not pollute the S&OP.

One of the key success factors is not to be polluted by operational issuesNirmal Govinda, Manager, spécialiste Supply Chain KEPLER

An S&OP is considered mature when the process:

- Plans for the medium term

- Keeps company goals in sight

- Leads to decision making

- Looks at different scenarios

- Integrates financial planning

- Offers measurable and understandable KPIs (animated monthly)

- Reconciles Operations and Finance

Supply Chain planning consulting, in 2022: what are we talking about?

1 – Implementation and/or review of the S&OP process

- Review of the process in place and benchmark against best practices

- Modelization

- Overhaul of the process: frequency of meetings, prerequisites, deliverables for each phase

- Definition of governance and the Roles & Responsibilities of each

- Team training

KEPLER added value in this area: functional expertise, diagnostic methodology, change management

2 – Project Management Assistance

The pandemic has accelerated the ongoing digital transformation, with an upsurge in projects underway or planned on the S&OP side.

- Fit & gap analysis between existing solutions and customer needs. Support on Call for

- Tender and selection of a tool

- Assistance in tool design: workshop for collecting requirements, formalization of functional needs, monitoring of implementation, testing, and acceptance

- Data recovery: identification of interface needs, data preparation, consistency analysis, and assistance

KEPLER added value in this area: functional expertise, AMOA, and Agile experience, and change management

* “S&OP is the single most important and critical cross-functional process. If S&OP is done properly, it leads to significant returns, including increased revenue and profitability.” Michael Youssef, Senior Director Analyst, Gartner (Avril 2021). – Source