Supplier Development: Winning Integration

This business model begins and ends with the customer. To apply this model, it is important to develop and maintain a supply base that is an integral part of the extended Supply Chain and that can consistently deliver the right part, in the right place, at the right time, in the right quantity, and of good quality.

Supplier Development, Background Reminders

Today’s Business Environment

It is characterized by:

- The changing complexity of the Supply Chain

- The need to integrate a supplier relationship

- The limit of internal resources, necessary for flexibility

- The increase in competition and the need for innovation

- A working environment managed in silos by a KPI

- An increasingly demanding market

For businesses to strengthen their customer focus and move from a limited mindset to a more open mindset, they must integrate their supplier base.

Supplier-customer relationships are a system that can optimize performance when all parties involved work to maximize it, sharing resources, trusting each other and genuinely working together to be always present for the end customer. Advice that is easier to state than to implement, and which does not happen overnight.

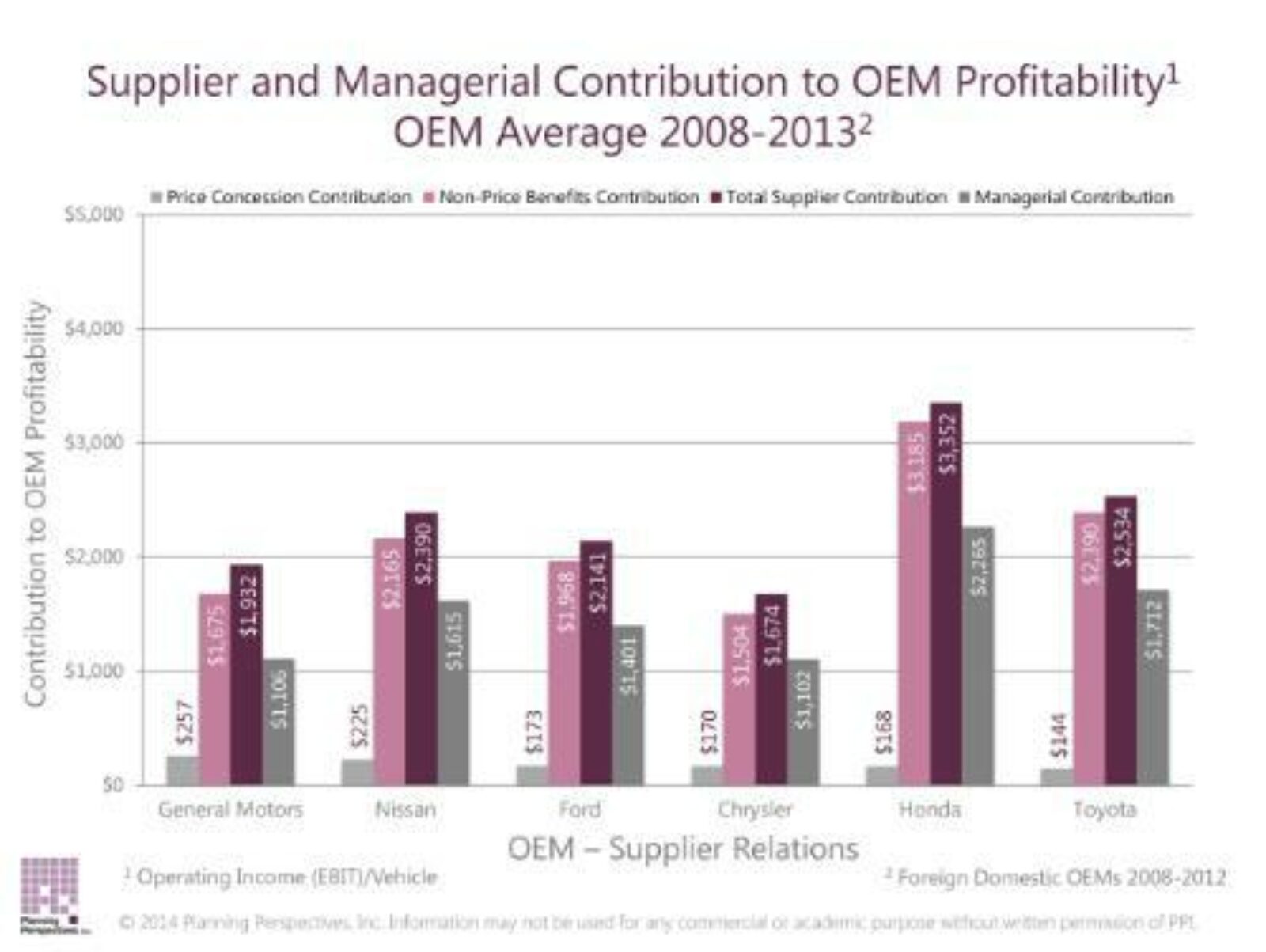

The supplier price concession contribution (shortest bar) is only a fraction of the total supplier contribution to OEM profits. When added to the supplier's non-price contribution (third bar from the left), the total exceeds the OEM managerial contribution (fourth bar) to OEM profits. (PRNewsFoto / Planning Perspectives, Inc.)

Supplier Development, a History

For Decades, Companies Have Deployed Supplier Development Programs With Varying Degrees of Success.

By deploying Lean initiatives and striving to integrate continuous improvement, companies have tried but often failed.

The fact is that the vast majority of these initiatives have been developed in silos: either in the company itself or in one of its departments, only marginally and occasionally involving the supplier base.

Another reason for failure is that such initiatives would focus on selected KPIs, driven by a “$” symbol, causing conflicts when the definition of these KPIs or their targets is not aligned with other performance indicators. performance of the company or any supplier:

- Without really addressing the cultural implication of the creation of real partnerships,

- Without having visionary leadership that understands the long-term implications,

- Without formulating a strategy that aims for a real change in the way supplier-customer relationships are thought out, developed and measured

… this initiative will continue to produce failures.

Monozukuri is a New Way of Approaching Supplier Development

Via supplier integration and a cross-functional effort that extends the benefits captured by optimizing the end-to-end Supply Chain, supplier development takes a new path that carries ambitions.

The Monozukuri is Created Using Three Pillars

- Nine Monozukuri levers

- A robust process

- Change management

These Non-Self-Supporting Pillars Require Three Favorable Factors of the Monozukuri

- Validated tools and techniques

- Aligned KPIs, Targets and Objectives

- Business culture

Monozukuri and Supplier Development, the Ingredients for Success

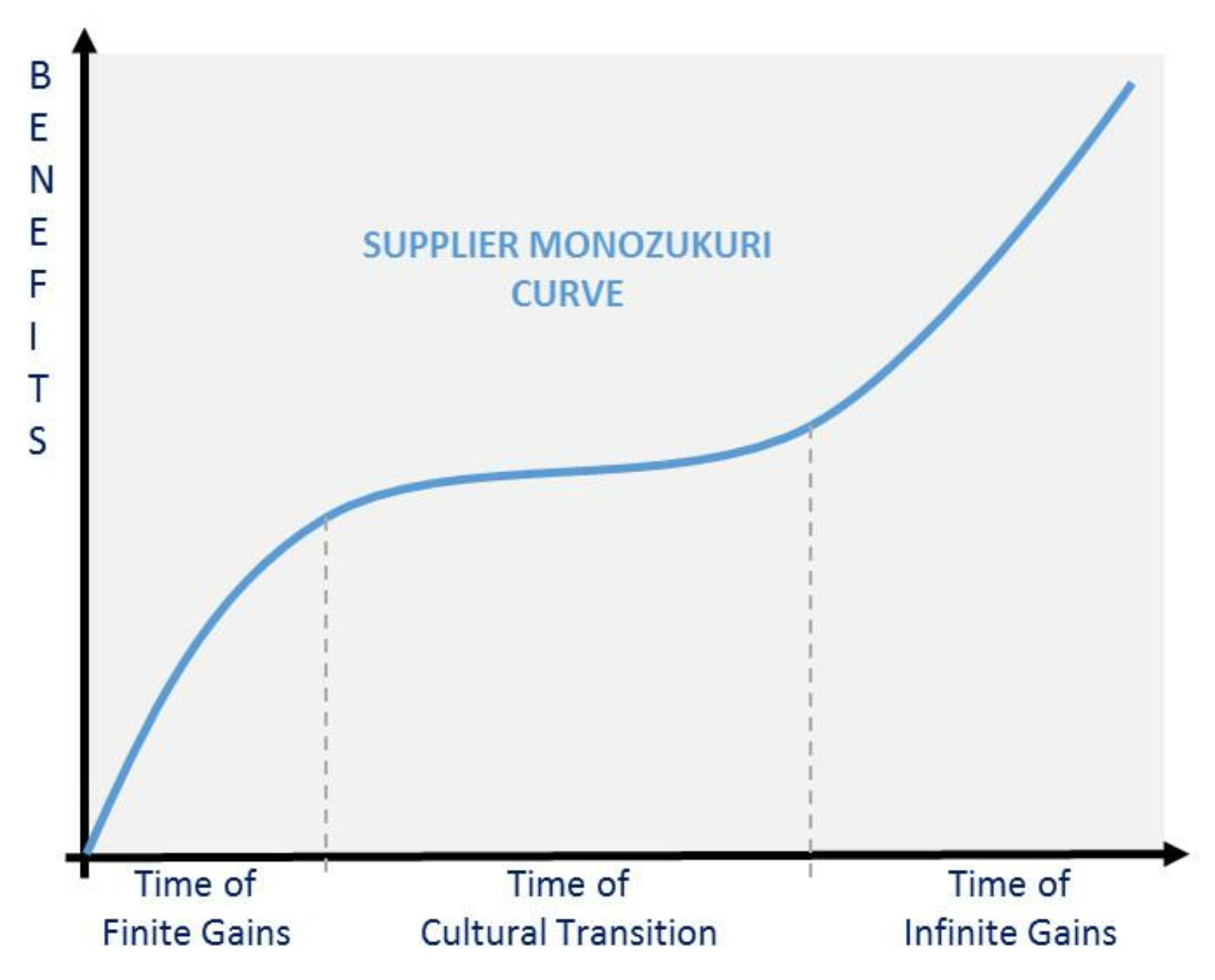

Communicating the Monozukuri vision correctly across the Supply Chain creates the momentum required to establish the enabling factors for Monozukuri and deploy the three pillars across the organization. Businesses should not underestimate the time and effort required to define and communicate the vision statement.

To support Monozukuri a business does not require as many resources as are needed to establish it. Once the Monozukuri engine is oiled and the system delivers perpetual benefits, it produces continuous improvement within the end-to-end supply chain and ultimately extends to the end customer.

Results should not be measured by the success or flaws of one or another KPI at any given time, but by how the system responds to any shortfall, understanding the true long-term impact for the final customer. This approach opens the way to working as “true partners”.

Whatever challenge you might face, confronting it with your business partners (strategic suppliers) will give you the competitive edge you need and provide a change management model that every element of the system will turn to, perpetuating the benefits for every party involved!